Creating CGI Bottles for Fever-Tree – Project Case Study

Our task was creating CGI bottles for Fever-Tree, and this blog post is about how we produced the content for the client, and the processes involved in making them.

We were asked to create photo-realistic CGI images of Fever-Tree’s entire range of flavours that, when completed, would be used as assets for all of their various worldwide markets and kept in a global image library.

To see a video breakdown of the production of the CGI bottles for Fever-Tree click the video below.

THE CREATING CGI BOTTLES FOR FEVER-TREE BRIEF

Our Client (Fever-Tree) provided us with all the necessary reference needed in order to recreate their entire product range realistically in CGI. The assets provided included all the physical bottles for us to measure accurately and recreate, the original printing files for the bottle labels and PDF blueprints of the bottles and their embossing to ensure complete accuracy.

THE CREATING CGI BOTTLES FOR FEVER-TREE PRE-PRODUCTION

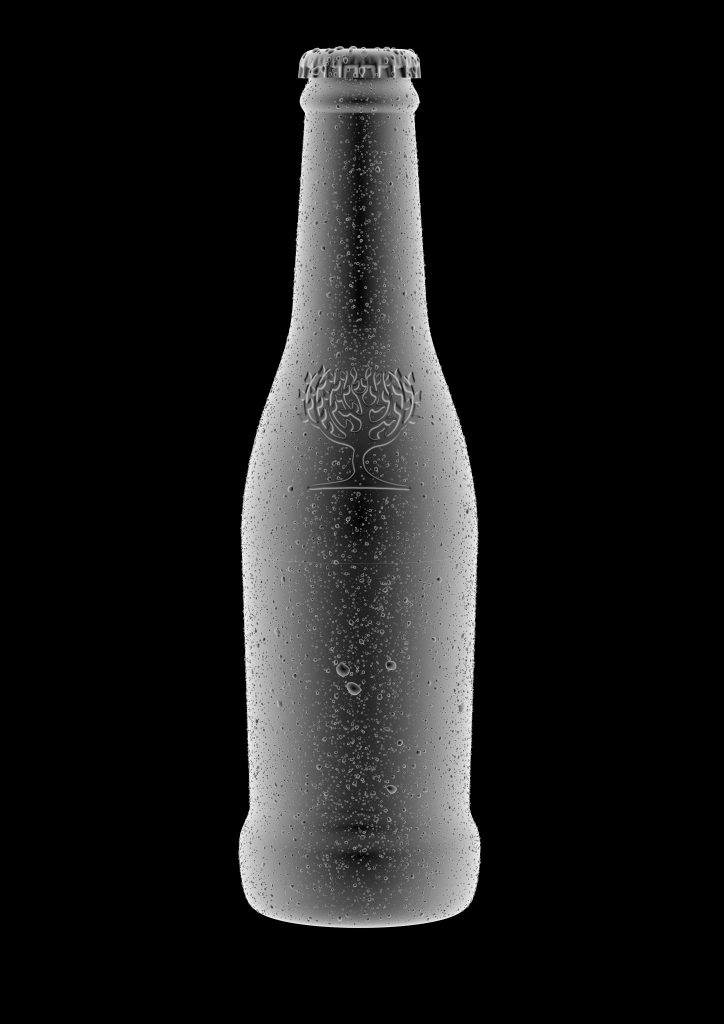

We arranged a creative consultation with the client going back and forth to ensure an accurate bottle design but also a desired look that would be applied across all of the bottles. We also went back and forth on other stylistic choices such as the evanescence and the look and positioning of the spritzing on the bottles, before settling on a final design. Below you will see a comparison of the look of the rendered bottle and the photography.

THE CREATING CGI BOTTLES FOR FEVER-TREE PRODUCTION

Following on from the initial consultation and the pre production stage, we would be required to produce 4242px x 6000px images for all of their bottles that were on current sale at a wide range of sizes.

The production involved four variants of the bottles (See image below), 2 size variants for the global market and 2 size variants for the German market:

- Worldwide 200ml

- Worldwide 500ml

- German 200ml

- German 500ml

After the client supplied to us their Matrix excel document which we converted into an easy to follow checklist in order for us to track which bottles had been completed, which ones were rendering and which ones were a priority.

The client provided us with access to their web portal which contained the original product photography for us to use as reference, especially in the case of the look of the liquid colour for some of the flavours such as Madagascan Cola and Smoky Ginger Ale.

We were also provided with the original source files for the bottle labels are used for real world printing on the actual bottles. With these files we were able to convert them so that they could wrap round and be placed on the 3D bottle.

Render Passes

As shown in the breakdown at the top of the page, here are detailed still images of each of the render passes that create the final bottle image.